Making a cord or rope with a core is not so easy in itself, and made in the traditional method the yarns would have been spun up into strands, and then the core positioned before the rope was laid up, the rope top having a central hole for the core strand to pass through.

Also due to the rope becoming shorter that the length of the strands as it laid up; the core would have to be managed by another set of hands.

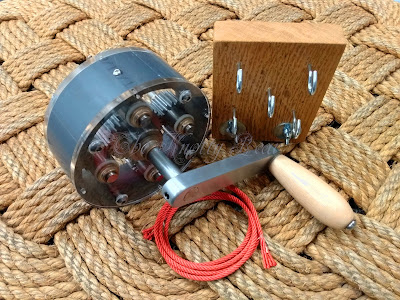

My cord maker, and cord making method being completely different from the traditional means that the above method will not work as the cord forms from the centre out, all the time the drill spinning at high speed, so no space, and not safe for another set of hands to manage the core at either end! however my cordmaker can be used single handed so friends or helpers are entirely optional.

So, after trialling several different ways that I could possibly use my cord maker to make a cord or rope with a core strand I finally came up with the one thing that actually works.

I attached a ball bearing swivel to the central hook on the machine, this allows the machine and hooks to rotate as intended without the the central core being over twisted or untwisted, as either of these would effect the lay of the final cord and its integrity.

At the opposite end of the cord/rope walk sits the outend; which replaces the traveller as the cord maker itself travels instead, I added a central hook here also and the core passes over this and off the bench, the end of the core strand is weighted to take up the slack as the strands are initially spun up.

Below you can see the core strand exiting the formed cord.